Rapid Reliability Prediction of Emerging Module Interconnect Technologies With Combined-Accelerated Stress Testing

DuraMAT evaluates the strengths and weaknesses of emerging interconnect designs for solar cells. The ability of combined-accelerated stress testing (C-AST) to screen multiple climates is applied for rapid reliability risk evaluation of these new technologies.

This work also incorporates field aging, finite element analysis (FEA), and failure analysis to examine the potential for a 50-year module life. The interconnect technologies differentiated using C-AST include electrically conductive adhesive and tape, monolithic conductive backsheet with laser welding to cells, multiwire with various cell spacings and wire geometries, and a low-temperature soldered wire interconnect for silicon heterojunction technology (HJT) cells—which was a major focus of this work.

In wire-interconnected samples, C-AST found that elevated temperature resulted in power loss of up to 9% in mini-module samples, with corresponding fill factor losses from interconnect and metallization degradation that were validated with field testing. Post-test characterization identified solder-gridline cracking, wire-cell separation, and screen-printed silver loss or breakage from the cell as contributing mechanisms. FEA demonstrated that wire-to-cell contact is maintained by contraction of the encapsulant after lamination, but the wire can lift off due to expansion of the polymer at elevated temperature.

Additionally, relative wire-to-cell displacements were detected during environmental simulations, driven in part by the surrounding polymer’s motion in response to changes in temperature and external mechanical load.

The PV module series resistance increases because of the encapsulant pulling the interconnect wire off of the cell as the encapsulant expands, and also because of the in-plane dimensional changes of the wire with temperature.

Core Objective

Disruptive Acceleration Science

Team Members

Peter Hacke, Nick Bosco, and David Miller at the National Renewable Energy Laboratory (NREL); and James Hartley, Sandia National Laboratories

Impact

The long-term performance of various metallization and interconnect types of modern PV modules were differentiated in C-AST. Degradation modes were confirmed by field testing, FEA, and microscopy. For example, with wire interconnects, we could forecast the occurrence of encapsulant delamination at the grid finger-wire connection, loss of contact between the wire and grid finger associated with thermal expansion (according to the temperature coefficient of expansion mismatch), and loss of silver metallization associated with wear or pull-off by the wire.

Learn More

Hacke, Peter, David Miller, Daniel Pierpont, and Tianyu Wu. 2023. “Performance and Durability of Electrically Conductive Tape for Shingled Si Heterojunction Technology Cells.” Progress in Photovoltaics: Research and Applications 33 (1): 16–26.

Hacke, Peter, Nick Bosco, James Hartley, David Miller, Govindasamy Tamizhmani, and Akash Kumar. 2024. “Reliability of Cell Interconnect Technologies in Modern Module Types.” Poster presented at the 2024 PV Reliability Workshop. Page 41.

Contact

To learn more about this project, contact Peter Hacke, NREL.

![b3a-hacke-interconnect-fig1 1st Principal Stress [Pa]: 1.0e+08, 7.5e+07, 5.0e+07, 2.5e+07, 0.03+00](/images/duramatlibraries/project-images/b3a-hacke-interconnect-fig1.jpg?sfvrsn=17e35e51_1)

Modeled cross section of wire showing liftoff of wire from cell at 90°C. Displacements scaled by 2.5x. Cell colored by first principal stress.

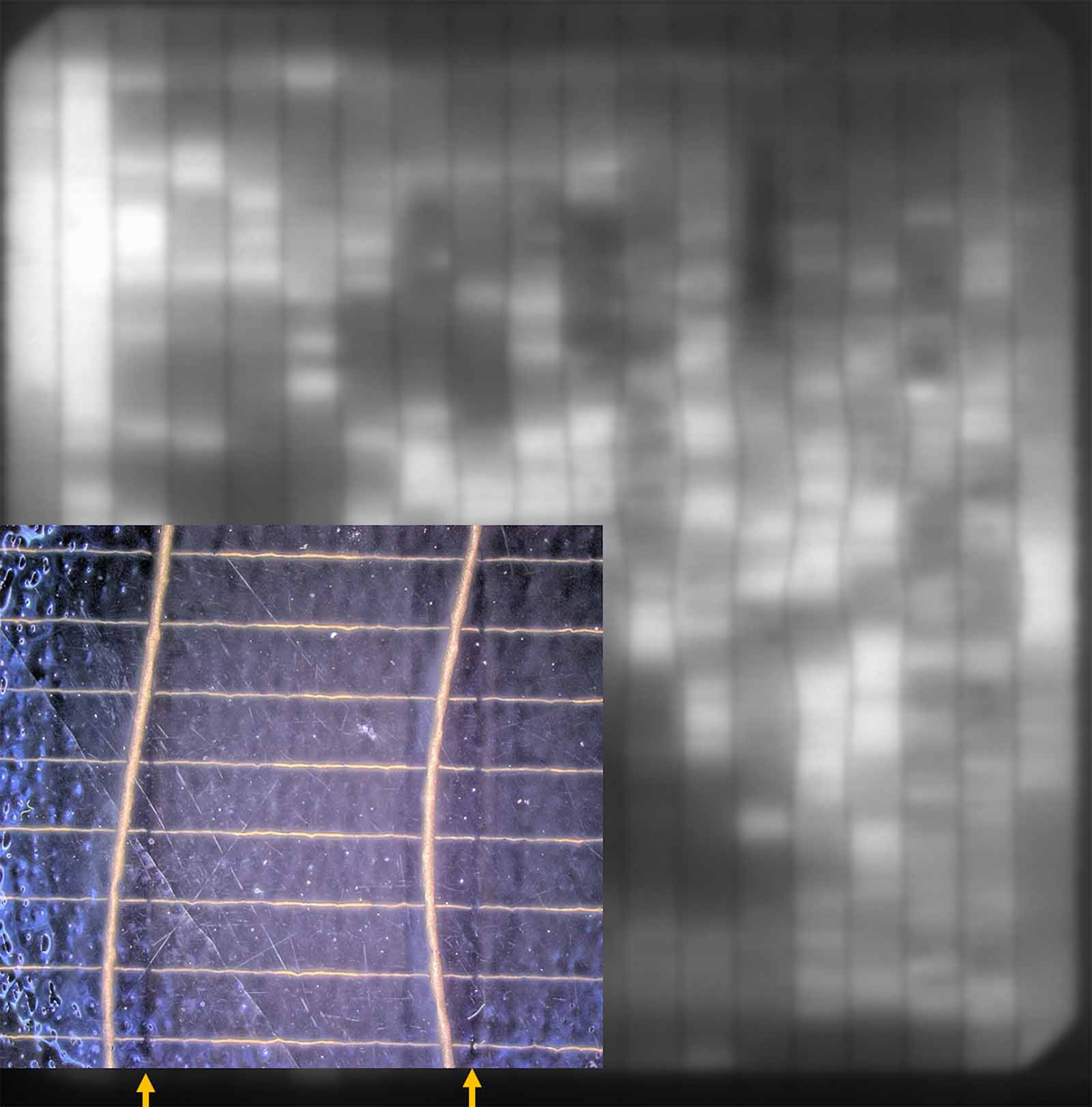

Wire pulling off silver from cell and buckling because of elevated temperature (inset), leading to asymmetric darkening in electroluminescence around wire position (at arrows).