Silicon Module Recycling via High-Power Lasers

DuraMAT aims to revolutionize photovoltaic (PV) waste management by developing a cutting-edge, sustainable recycling process. This approach uses a laser-based recycling solution to address critical environmental challenges associated with end-of-life PV modules.

These modules contain valuable materials like silicon, silver, and glass, which can be reclaimed to reduce environmental impact and ensure proper waste management. Current recycling methods are often neither cost-effective nor environmentally sustainable, and the laser approach can help overcome these challenges.

An innovative PV module recycling technique using high-power lasers allows recovery of glass and silicon for reuse. The initial cost analysis shows that the laser technique is cost-effective. The developed technique also offers environmentally friendly solutions for PV waste recycling.

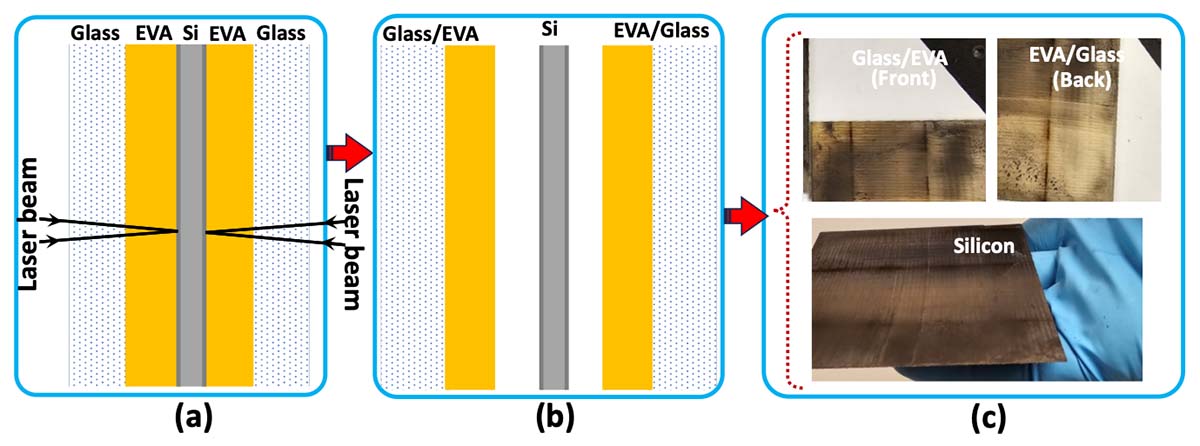

PV modules are designed to last over 30 years and contain fragile materials like glass and silicon, making them difficult to dismantle. Our laser recycling technique offers a breakthrough solution. Precisely directing a focused laser beam at specific interfaces within the module causes localized heating, thereby breaking interfacial bonds. This enables controlled separation of glass from silicon. The laser process parameters have been optimized for high throughput, low cost, and recovery of materials without causing breakage.

The laser-based recycling process enables the recovery of high-quality glass with approximately 92% optical transparency—comparable to new glass used in PV modules. This reclaimed glass is ideal for reuse in new solar panels and other applications requiring high optical transparency. We also achieved a remarkable milestone in recovering silicon wafers without breakage. Reclaiming materials via our laser recycling process offers immense potential for reuse in new solar cells, semiconductor devices, and greenhouse applications. The reclaimed silicon wafers can also serve as a valuable feedstock for future silicon production for PV modules and semiconductor devices, contributing to more sustainable manufacturing practices.

This laser-based recycling method not only mitigates the environmental hazards associated with PV module disposal but also supports the recovery of valuable materials for future reuse.

Core Objective

Team Members

Mool C. Gupta, Pawan K. Kanaujia, and Abhishek Trivedi at the University of Virginia; and David Young, Michael Owen-Bellini, and Heather Mirletz at the National Renewable Energy Laboratory

Impact

The laser recycling technique has a major impact on PV waste management via the cost-effective recovery of materials such as glass, silicon, and silver. The technique offers an economical, environmentally friendly solution for PV recycling. The project goal supports the circular economy by reclaiming valuable materials for future reuse.

Learn More

Gupta, Mool, Pawan Kanaujia, Michael Owen-Bellini, Michael Woodhouse, and David Young. 2024. “Water-Jet-Assisted PV Module Recycling.” In Proceedings of SPIE PC13027, Energy Harvesting and Storage: Materials, Devices, and Applications XIV PC1302704.

Kanaujia, Pawan, Michael Owen Bellini, Michael Woodhouse, David Young, and Mool Gupta. 2024. “Recovery of Glass and Silicon Solar Cells From Si-Modules Through Laser Processing.” Presented at the 52nd IEEE Photovoltaic Specialists Conference, Seattle, Washington, June 2024.

Data Presented at DuraMAT’s Fall Workshop and Program Review held in Albuquerque, NM, in September 2023, and Berkeley, California, at Lawrence Berkeley National Laboratory in September 2024.

Gupta, Mool and Pawan Kanaujia. 2023. Laser Process and System and Resultant Article of Manufacture. U.S. Patent Application No. PCT/US2023/076447. Patent application filed October 10, 2023 (waiting for approval).

Gupta, Mool and Pawan Kanaujia. 2024. Laser Process and System and Resultant Article of Manufacture. U.S. Provisional Patent Application No. 63/538, 209. Patent application filed September 13, 2024 (converted into main patent and waiting for approval).

Contact

To learn more about this project, contact Mool C. Gupta, University of Virginia.

Schematics of (a) laser irradiation from the front and back sides of a bifacial PV module and (b) laser separation of silicon and glass. (c) Images of recovered module components. Images from Pawan Kanaujia, University of Virginia