Multifunctional and Durable Engineered Glass for Photovoltaic Applications

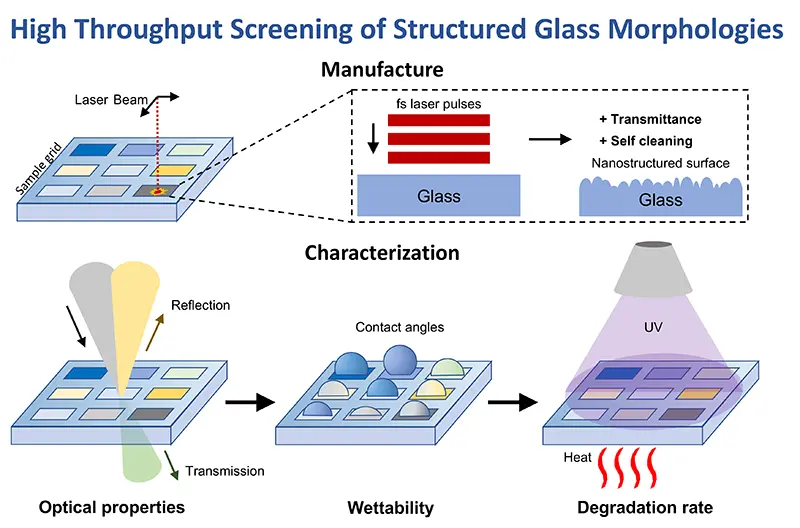

This DuraMAT project is using femtosecond laser processing and high-throughput analysis of both wettability and reflectivity to screen 10,000 unique morphologies to determine the anti-reflectance and self-cleaning potential of photovoltaic (PV) glass surfaces.

Surfaces identified as having both these characteristics will undergo accelerated aging to determine the patterns that maintain these properties after experiencing real-world stressors. We expect increased durability for the lifetime of the cell as these patterns are integrated into the glass itself and do not rely on chemical bonding or ultraviolet-sensitive coatings. This work is anticipated to guide the design of structured glass that will increase the cost-effectiveness of PV cells by improved long-term solar power transmission in harsh environments.

A well-designed solar panel maximizes the sunlight passing the glass surface for electricity conversion in the PV cell. Reflections off bare glass surfaces lead to efficiency losses which become exacerbated when dirt accumulates under long-term exposure to real-world conditions. Multifunctional coatings have been developed to combat these issues with self-cleaning and antireflective properties. Current coatings require chemical processing and often fail to last the lifetime of a cell, especially in harsh environments. An alternative approach to chemical coatings is patterning micro/nano scaled structures onto the glass surface, but little work has been done to optimize these structures.

Core Objective

Location

Lawrence Berkeley National Laboratory

Applications

The screening method used in this project is anticipated to discover multiple surface structures that can increase the energy harvesting capabilities of a solar cell by avoiding losses from glass reflection and soiling through self-cleaning. Once these morphologies are discovered, they can be implemented into different panel manufacturing processes for scale up and field testing in various real-world environments. The high-throughput screening method can also be used to develop new surfaces for other materials including flexible solar panel top sheets.

Availability

Available to DuraMAT collaborators.

References

[1] IEEE Journal of Photovoltaics 11(3), 760 (2021)

[2] Solar Energy Materials & Solar Cells 98, 46 (2012)

[3] Adv. Mater. 31, 1901123 (2019)

[4] Nanotechnology 17, 3234 (2006)

[5] Adv. Materials 20, 4049 (2008)

[6] Appl. Phys. Lett. 96, 093702 (2010)

Contact

To learn more about this project, contact Vassilia Zorba.