Durability of Modules Utilizing Screen-Printed Copper Contacts

This DuraMAT project will establish metrics for solar cell durability or silicon solar cells employing copper (Cu) fire through pastes for metallization that translate into the established International Electrotechnical Commission’s damp heat protocols for silicon modules.

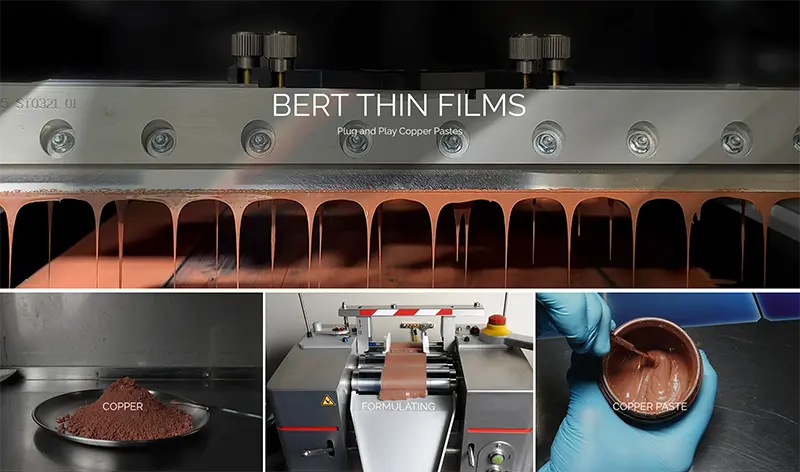

The degradation pathways of the Cu paste at the photovoltaic module level will be studied with results detailing formulation and processing windows to produce a durable module. With the industry trying to increase production significantly, it is imperative that silver (Ag) metallization strategies be replaced with lower cost metals, specifically Cu.

Core Objective

Locations

Bert Thin Films, LLC, Georgie Institute of Technology, and the National Renewable Energy Laboratory

Applications

The industry has been very interested in replacing Ag with lower cost and abundant Cu but has resisted primarily on the potential accelerated degradation including copper diffusion into silicon, oxidation, and ethylene vinyl acetate reaction. This project aims to develop accelerated aging tests that explore the impact of diffusion, oxidation, and encapsulant degradation mechanisms.

Availability

NREL scientists

References

Yuchao Zhang, Kim, M., Wang, L., Verlinden, P. and Hallam, B. (2021) “Design considerations for multi-terawatt scale manufacturing of existing and future photovoltaic technologies: challenges and opportunities related to silver, indium and bismuth consumption”, Energy and Environmental Science, 14 (11) pp5587-5610, DOI 10.1039/D1EE01814K

Sang Hee Lee, Lee, D.W. and Lee, S. H. (2017) “Review of Conductive Copper Paste for c-Si Solar Cells” Korean Journal of Metals and Materials, 55 (9) pp637-644, DOI 10.3365/KJMM.2017.55.9.637

Contact

To learn more about this project, contact Thad Druffel.