Degradation in Glass/Glass Bifacial PV With Emerging Encapsulants and Half-Cut Cells

DuraMAT's sequential stress testing has identified degradation modes related to unstable rear-side passivation layers on bifacial photovoltaic (PV) cells.

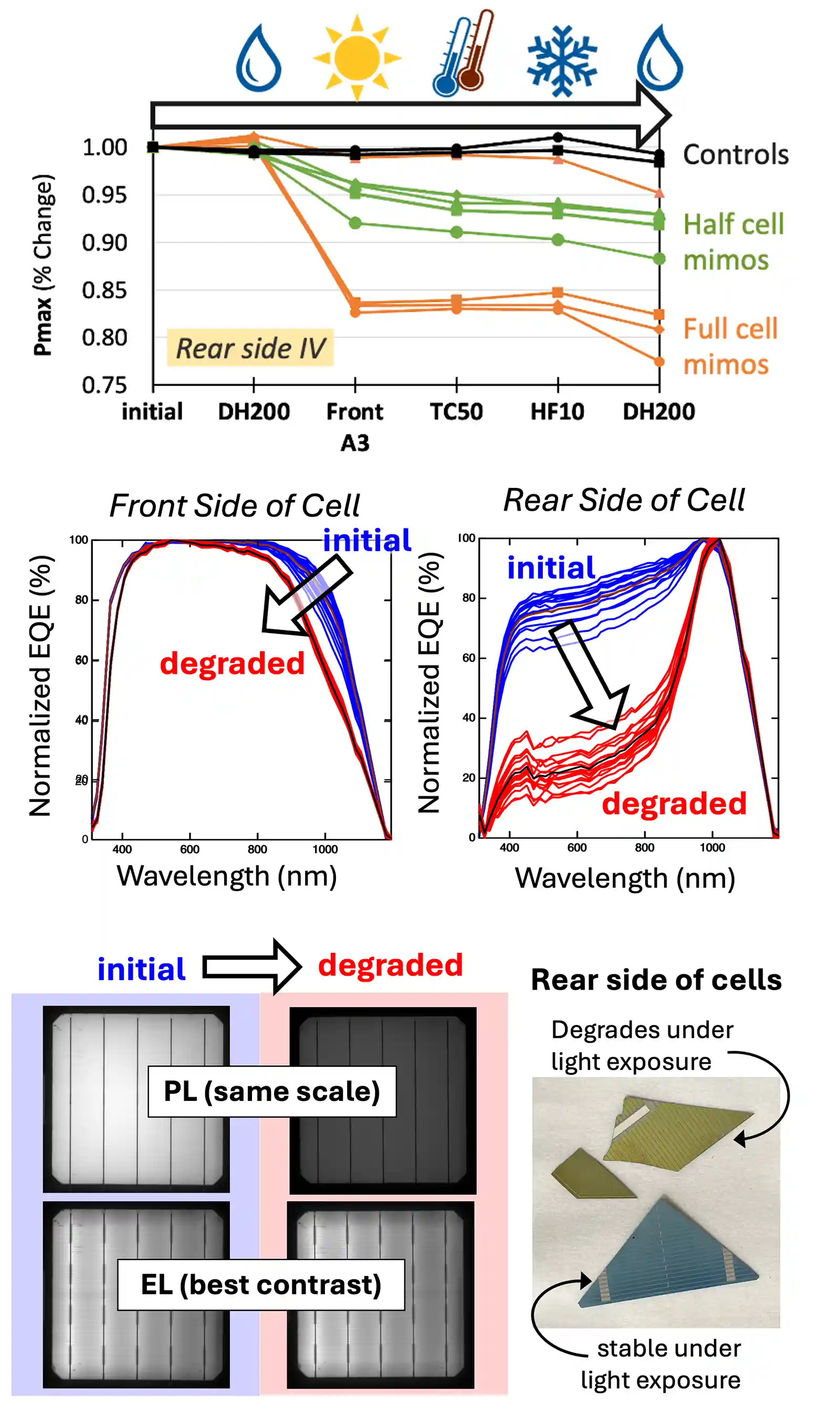

Sequential stress testing can identify durability issues for bifacial crystalline silicon PV modules beyond those caught by existing qualification tests. Here, we study bifacial cells with variations in the rear-side color ranging from blue to yellow, indicating inconsistencies in rear-side cell passivation. We apply a modified IEC 63209-2 sequential stress procedure, consisting of damp heat (DH200), full-spectrum light exposure (A3-2000), thermal cycling (TC50), and humidity/freeze (HF10).

We observe a 1%–2% rear-side power increase after the initial DH200 stress step, followed by up to 17% degradation for subsequent UV-visible light exposure incident on the front side of the short-circuited cells for 2,000 hours at 20% relative humidity and 65°C air temperature (90°C black panel). This result, combined with additional control test sequences, shows that the stressor sequence of damp heat followed by light exposure is required to produce this degradation mode, and that degradation may not occur under light exposure alone.

Interestingly, we observe less degradation for half-cells compared to full-cell mini-modules. Additionally, we observe that cells with greater yellowness on the rear side begin with higher voltages but exhibit more severe degradation. Nondestructive methods, including the PV external quantum efficiency and imaging with photoluminescence and electroluminescence, reveal degradation signatures of rear-side surface recombination.

Core Objective

Team Members

Dana Kern, Rebecca Wai, Steve Johnston, Paul Ndione, Dennice Roberts, Michael Owen-Bellini, Laura Schelhas, Soňa Uličná, John Mangum, and Kent Terwilliger at the National Renewable Energy Laboratory (NREL)

Impact

Our results show that new degradation modes can arise under sequential stress testing that might not be observed with individual stress tests. This informs the development and adoption of sequential stress testing for evaluating long-term durability analysis in silicon PV.

Learn More

Kern, Dana, Soňa Uličná, Kent Terwilliger, Jimmy Newkirk, Steve Johnston, and Dennice Roberts. 2024. “Sequential Accelerated Stress Testing Identifies Processing Defects in Bifacial Photovoltaic Module Packaging That Limit Durability.” Presented at the 2024 IEEE 52nd Photovoltaic Specialists Conference, Seattle, Washington.

Contact

To learn more about this project, contact Dana Kern, NREL.

The sequential stress testing sequence results in high power loss after light exposure, which is more severe for full-cell mini-modules than for half-cell mini-modules. Changes in external quantum efficiency (EQE) indicate rear-side passivation loss upon degradation. Photoluminescence (PL) imaging shows a uniform intensity decrease, consistent with increased carrier recombination. Electroluminescence (EL) imaging shows a minimal change in contrast, indicating no change in the electrical contact quality. Photos of the rear sides of the cells demonstrate significant variation in rear-side color, indicating inconsistency in cell processing. Images by Dana Kern, Rebecca Wai, Steve Johnston, Paul Ndione, Dennice Roberts, Michael Owen-Bellini, Laura Schelhas, Soňa Uličná, John Mangum, and Kent Terwilliger, NREL