Degradation Mechanisms and the Role of Sequenced Accelerated Testing To Ensure Long-Term Solar Module Encapsulation

DuraMAT has developed a multi-scale mechanics model based on photovoltaic (PV)-specific degradation reaction kinetics that connects the encapsulant mechanical properties to the degrading polymer molecular structure and interfacial bond density with the adjacent solar cell and glass substrates.

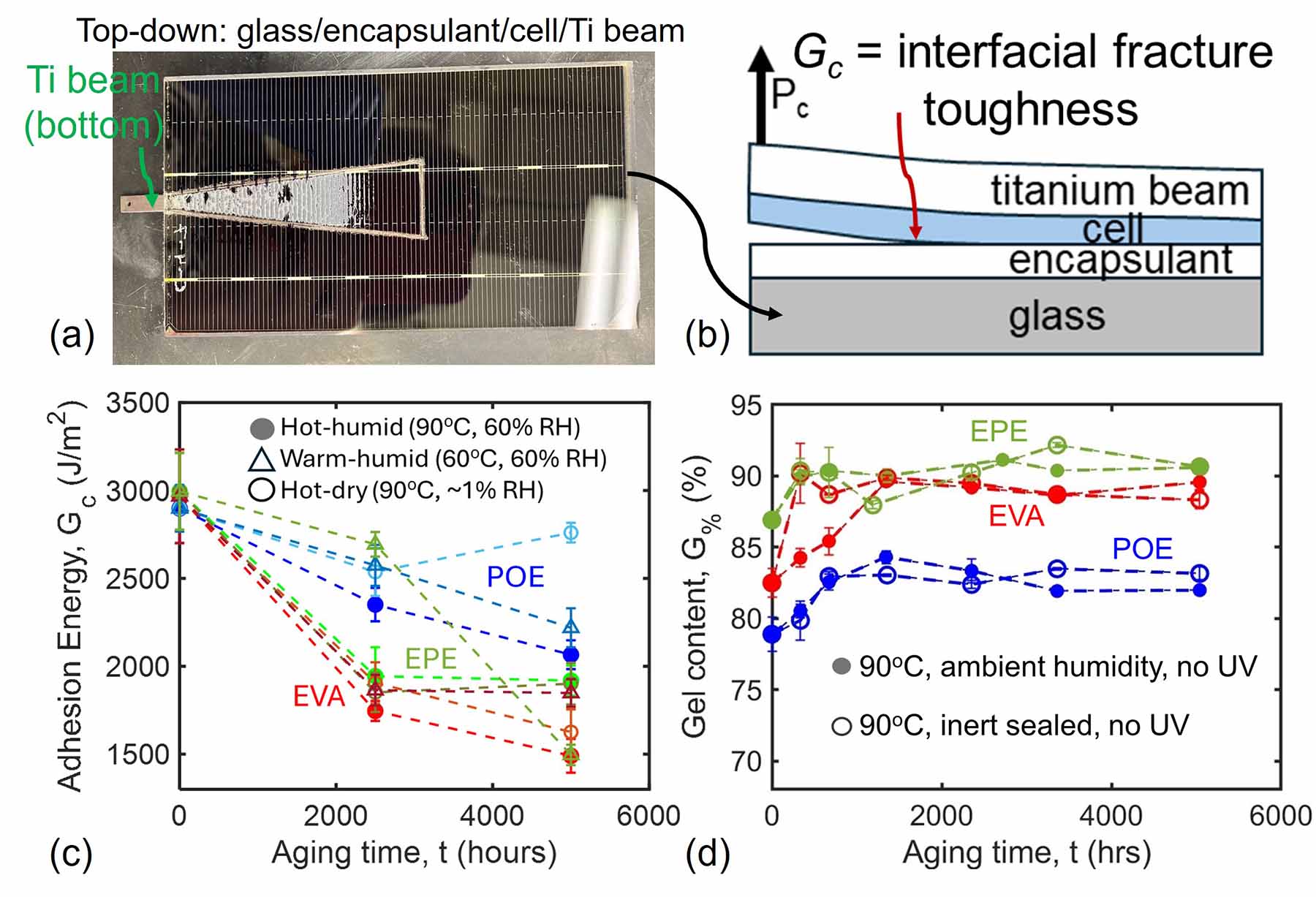

We are validating the model with experimental characterization of encapsulants and representative coupons (cell/encapsulant/glass laminates) after selecting accelerated aging conditions and sequenced exposures. Coupon adhesion testing showed significant decreases in the adhesion energy, Gc, of ethylene-vinyl acetate (EVA)/cell and EVA/ polyolefin elastomer (POE)/EVA (EPE)/cell interfaces after 5,000 hours of hot-dry (90°C, ~1% RH [relative humidity]), hot-humid (90°C, 60% RH), and warm-humid (60°C, 60% RH) aging (panel (c) in the figure). The POE/cell interface retained a high Gc after hot-dry aging but degraded under hot-humid and warm-humid aging, demonstrating the role of moisture in accelerating hydrolytic depolymerization reactions at the encapsulants’ interfaces. Note that despite interfacial degradation, the Gc values are still significantly above the spontaneous critical field delamination threshold of ~160 J/m2.

Adhesion testing on EVA coupons after hot-humid (90°C, 60% RH) aging verifies faster hydrolytic depolymerization at the encapsulant interface compared to hot-dry (90°C, ~1% RH) aging, but both conditions degrade the adhesion energy significantly. POE coupons exhibited the best stability after exposure with all accelerated aging conditions.

Degradation of the mechanical characteristics of encapsulants, leading to embrittlement and delamination, remains a leading cause of premature failure in PV modules. Ensuring module lifetimes beyond 30 years require advanced predictive modeling, which must include the fundamental materials degradation pathways and their dependence on operating temperature, UV, and moisture.

Core Objective

Disruptive Acceleration Science

Team Members

Reinhold Dauskardt and Kuan Liu at Stanford University; and David Miller and Nick Bosco at the National Renewable Energy Laboratory (NREL)

Impact

Using accelerated aging to study the degradation of encapsulation materials (EVA, POE, EPE) and their interfaces with the silicon cell and glass provides valuable new tools to prevent encapsulant field delamination. The predictive model developed in our program enables the PV community to understand how encapsulant material selection, module processing conditions, and field conditions affect interfacial degradation rates and the corresponding lifetime that may be achieved prior to delamination events.

Learn More

Datasets

Journal Publications

Liu, Kuan, David Miller, Nick Bosco, Jimmy Newkirk, Tomoko Sakamoto, and Reinhold Dauskardt. 2024. “Investigating the Crosslinking, Degradation, and Adhesion Behavior of Photovoltaic Encapsulants Under Thermal Accelerated Aging.” Accepted to IEEE Journal of Photovoltaics.

Liu, Kuan, Patrick Thornton, Dagmar D'hooge, and Reinhold Dauskardt. 2023. “Predicting Encapsulation Delamination in Photovoltaic Modules Using Photochemical Reaction Kinetics and Fracture Mechanics.” Progress in Photovoltaics 32 (5): 317–329.

Conference Proceedings

Liu, Kuan, David Miller, Nick Bosco, and Reinhold Dauskardt. 2024. “Determining the Crosslinking and Degradation Reaction Kinetics in Photovoltaic Encapsulants Using Accelerated Aging.” IEEE 52nd Photovoltaic Specialists Conference, Seattle, Washington, 0909–0914.

Published Presentations

Liu, Kuan. 2024. “Predictive Mechanics and Photochemical Degradation Kinetics Modeling for Polymeric Encapsulants.” April 2024 DuraMAT webinar on YouTube.

Liu, Kuan, David Miller, Nick Bosco, and Reinhold Dauskardt. 2024. “Predictive Mechanics and Photochemical Degradation Kinetics Modeling for Polymeric Encapsulants.” In Proceedings of the 2024 NREL Photovoltaic Reliability Workshop, Lakewood, Colorado, February 28, 2024.

Webpages

Stanford Engineering Dauskardt Group: Solar Reliability

Contact

To learn more about this project, contact Reinhold Dauskardt, Stanford University; and David Miller, NREL.

(a) Adhesion testing of coupon. (b) Schematic. (c) Gc of samples under hot-humid versus warm-humid versus hot-dry aging. (d) The gel content (degree of cross-linking) of encapsulants under high-temperature aging for up to 5,000 hours, measured with Soxhlet extraction. Images from Kuan Liu, Stanford University