Cross-Sectional Depth Profiling of Accelerated and Field-Aged Backsheet Materials

DuraMAT investigates the different degradation modes of individual backsheet layers for polyolefin- and polyethylene-terephthalate-based backsheets.

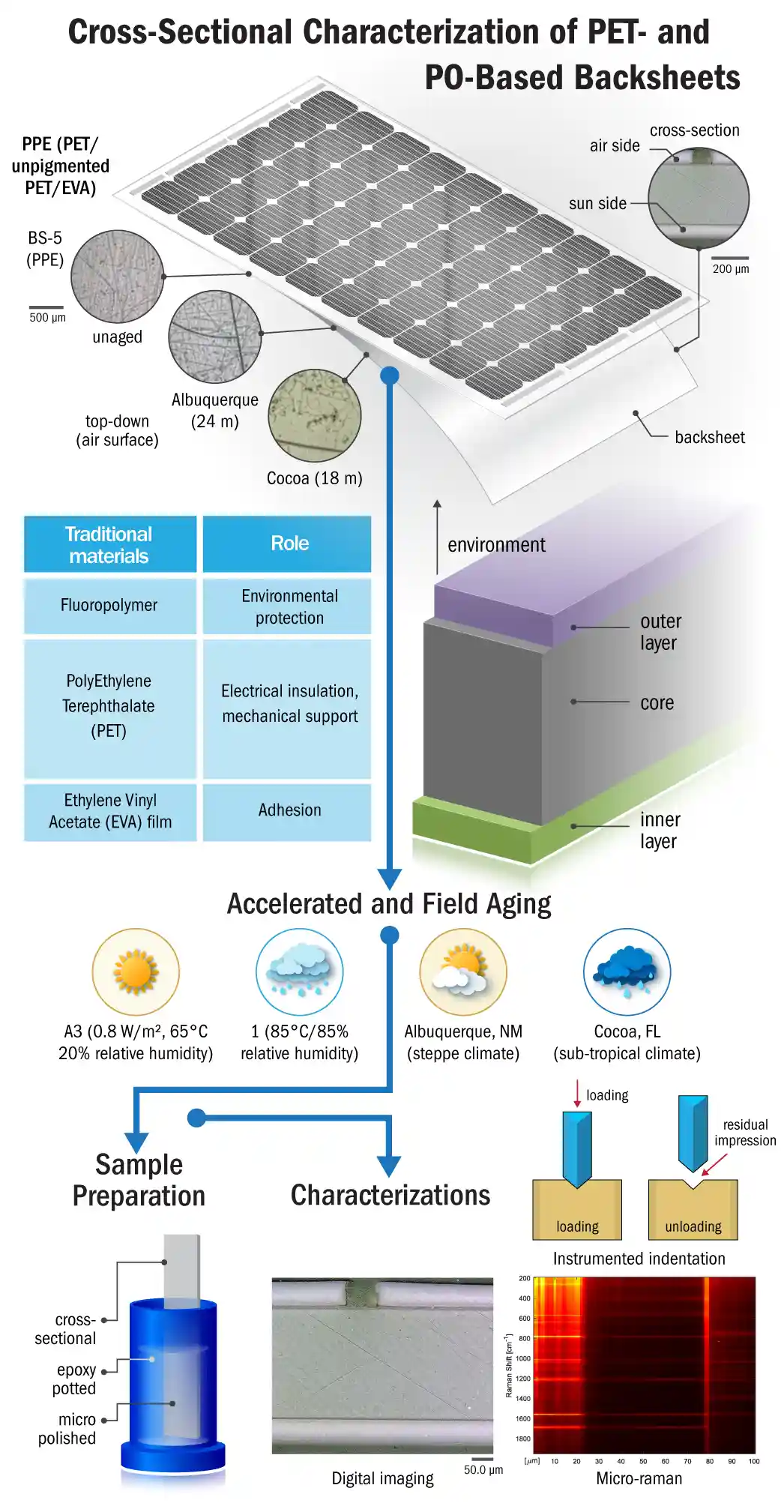

Photovoltaic (PV) module backsheets are multilayer composites where each layer has a specific purpose, including protection from the environment, electrical insulation, mechanical support, or adhesion. Backsheets are usually characterized by surface or bulk techniques. This does not provide a complete understanding, because each layer may degrade differently. Moreover, the separate layers are further complicated by different pigments and additives. Cross-sectional characterization is critical to identifying the dominating degradation modes for each layer.

In this work, polyolefin (PO)- and polyethylene terephthalate (PET)-based backsheets subjected to accelerated and field aging from the DuraMAT BACKFLIP project were characterized by cross-sectional techniques and compared to surface and bulk characterization results. Core layers remained chemically and mechanically intact; however, the inner and outer layers were more susceptible to degradation. Most notably, the PET-based backsheet experienced inner layer cracking after A3 UV weathering and field aging, a degradation mechanism noted in the field.

Core Objective

Team Members

Elizabeth Palmiotti and David Miller at the National Renewable Energy Laboratory (NREL); Jennifer Braid, Steven DiGregorio, Jessica Kopatz, Christine Roberts, and Bruce King at Sandia National Laboratories; and Peter Pasmans and Chris Thellen at Endurans/Worthen

Impact

Backsheets are often characterized by only surface and/or bulk techniques. This work demonstrates that cross-sectional characterization is critical to understanding the dominant degradation mechanisms of each backsheet layer and thus the reliability of the backsheet as a whole.

Learn More

DuraMAT DataHub: Backsheet Depth Profile Project

Contact

To learn more about this project, contact Elizabeth Palmiotti, NREL.

Cross-sectional characterization of PET- and PO-based backsheets. Illustration by Al Hicks, NREL