Unified Constitutive Model for Predicting Electrically Conductive Adhesive Degradation

DuraMAT will develop the framework for a unified constitutive materials model for electronically conductive adhesives (ECA), which will allow for the assessment of the new interconnect’s durability and reliability.

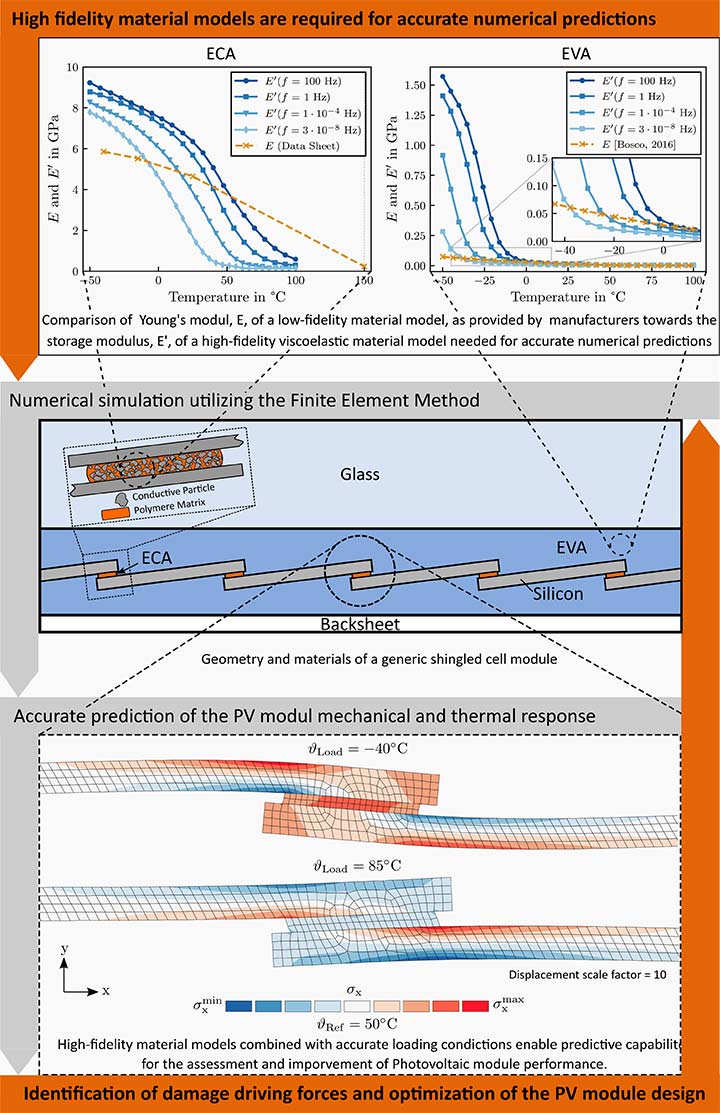

To achieve this goal, this work utilizes a three-layered approach: (i) materials characterization, (ii) numerical modeling, and (iii) validation. The mechanical and fracture mechanics properties of various ECAs marketed for the photovoltaic (PV) industry have been characterized and suitable, high-fidelity materials models were formulated. Those models were used within finite element simulations to assess the likelihood of interconnect failure during accelerated stress testing of PV modules. Long-term exposure measurements are ongoing which, when concluded, will allow for the validation of the developed unified constitutive model.

Background

New interconnect schemes that replace metallic solders with ECA appear in recent embodiments of crystalline silicon PV modules. These include shingled cell designs (SunPower, Seraphim, Solar City, Solaria). It also includes more traditional tabbing ribbon approaches, where the ECA directly replaces Pb-Sn and Pb-free Sn-rich solders.

Despite this significant materials change, the durability of these modules continues to be assessed with accelerated tests developed using empirical, and more recently phenomenological, models that describe the thermomechanical (creep-fatigue) response of eutectic Pb-Sn solder.

We should not expect that the fundamentally different material and bonding scheme of ECA—a polymer-matrix, metal-filled composite—will exhibit similar degradation mechanisms, kinetics, or acceleration factors to metallic solders. Therefore, an evaluation of the durability of these modules with the current, inappropriate, test methods yields an irrelevant result and interpretation that in no way represents the long-term performance of these systems.

The consequence of proceeding with this status quo of durability testing developed for metallic solders may be the premature and catastrophic failure of these innovative modules that would result in irreparable damage to the PV industry.

Core Objective

Multi-Scale, Multi-Physics Modeling

Location

National Renewable Energy Laboratory

Applications

The outcome of this research will provide a reliability model for the specific ECA’s investigated, and the metrology to develop this model for any similar class of materials. This project will allow the user to accurately interpret accelerated test equivalency and predict ECA degradation through any on-sun exposure.

Availability

All work will be published in the public domain.

References

M. Springer and N. Bosco. Environmental Influence on Cracking and Debonding of Electrically

Conductive Adhesives. Engineering Fracture Mechanics (accepted)

M. Springer and N. Bosco. Linear viscoelastic characterization of electrically conductive

adhesives used as interconnect in photovoltaic modules. Prog Photovolt Res Appl. 2020;

1– 23. https://doi.org/10.1002/pip.3257

N. Bosco, and M. Springer. Investigation of Failure Modes, Mechanisms and Driving

Forces for Electrically Conductive Adhesives as Interconnects in PV Modules. Proceedings

virtual EUPVSEC 2020

M. Springer and N. Bosco. Environmental Influence on Fracture and Delamination of

Electrically Conductive Adhesives. Proceedings virtual EUPVSEC 2020

N. Bosco, J. Hartley, and M. Springer. Multi-Scale Modeling of Photovoltaic Module

Electrically Conductive Adhesive Interconnects for Reliability Testing. Proceedings

virtual PVSC 2020

N. Bosco, M. Springer, Towards unified constitutive model for the degradation of electrically

conductive adhesives, In: 8th Workshop on Metallization & Interconnection for Crystalline

Silicon Solar Cells Konstanz, 2019, 2019.

Contact

To learn more about this capability, contact Nick Bosco.