Development of Flexible Panel Front Sheet with 25-Year Rated Lifetime

DuraMAT focuses on testing and predicting the lifetime for transparent front sheets by experimentally determining the photothermal degradation acceleration factor and applying it to an expected mission profile.

As photovoltaic (PV) costs have come down, distributed generation (DG) PV, by nature, has remained more expensive with higher planning, permitting, logistics, site preparation, balance of systems, and installation costs. To substantially reduce installed cost and approach the Solar Energy Technology Offices DG levelized cost of energy (LCOE) targets of 4-5c/kWhr (as shown in Figure 1), all aspects of project costs must be addressed. In addition, as cell, module, racking and inverter costs continue to decrease, soft costs have stayed persistently high, some of which may be addressed by changes to the hardware.

One approach to drastically reduce installed system cost is to redesign the module for total system cost reduction. This could manifest itself as a lightweight, conformable, and direct to roof-attached module. In this way, one eliminates the mechanical balance of system (mBOS) and associated logistics, supply chain, and installation costs. By eliminating the mBOS, modules must now attach directly to non-flat roofs and thus must have some compliance to accommodate bumps and slopes. As a result, an unframed, non-rigid module may be preferred.

Critical to these flexible modules is the front sheet which must enable a high efficiency, high reliability, long lifetime, and low-cost module. Traditional flexible module front sheets are fluoropolymers such as ethylene tetrafluoroethylene (ETFE) or fluorinated ethylene propylene (FEP), which are generally high cost and difficult to process. A lower cost front sheet comparable to PV glass is critical to reach sustainably low flexible module costs.

Core Objective

Location

SunPower Corporation and National Renewable Energy Laboratory

Applications

Residential, commercial, and power plant PV applications. This program demonstrates how to evaluate the lifetime of the front sheet under flexible PV mission profile and provide insight on the failure modes and design criteria of these components.

Availability

Reports are publicly available.

References

Sunshot 2030 fact sheet: https://www.energy.gov/sites/prod/files/2018/05/f51/SunShot%202030%20Fact%20Sheet.pdf

Augusto, A., Tyler, K., Herasimenka, S.Y., & Bowden, S.G. (2016). Flexible modules using <70 μm thick silicon solar cells. Energy Procedia, 92, pp. 493-499.

H. Ng, S. Hoang, D. Okawa et al., “25 Year Low Cost Flexible Front Sheet - Lifetime Prediction,” in NREL PV Reliability Workshop 2020. Available: https://www.nrel.gov/pv/pvrw.html

Contact

To learn more about this project, contact David Okawa.

![Images of 1-EFTE, 12-Fluoro-coated PFT, and 5-Stablized Mono-PET [med] module front sheets, three Initial and three High Desert-3.](/images/duramatlibraries/project-images/flexible-panel-front-sheet-1.jpg?sfvrsn=63443897_1)

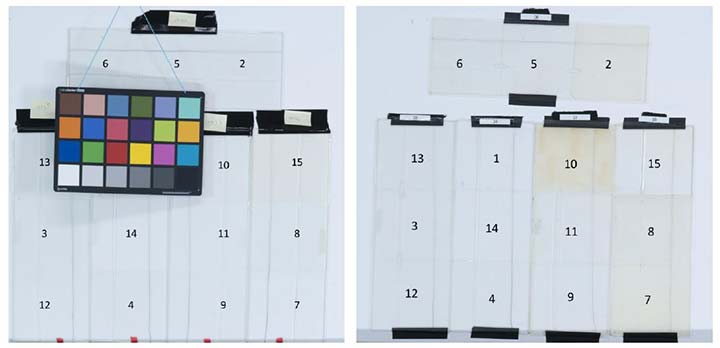

Figure 1. Mini-modules with various front sheets before and after the full C-AST exposure.

Figure 2. Fifteen front sheet candidates before and after C-AST screening.