Electromechanical and Mechanical Stress Testing of Grid Fingers, Busbars, and Modules

As a DuraMAT project, Osazda Energy and its team—the University of New Mexico, Georgia Institute of Technology, and National Renewable Energy Laboratory—are conducting electromechanical testing on grid fingers and bus bars. This includes accelerated mechanical stress testing on photovoltaic (PV) modules.

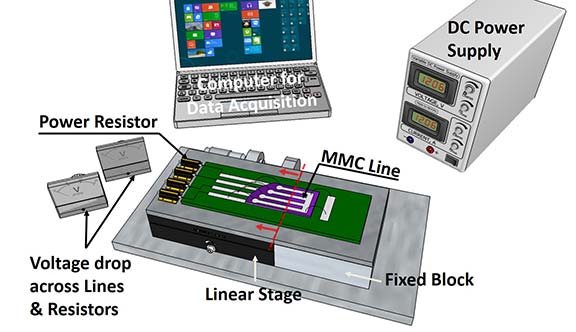

Particularly, resistance across cleaves and cracks (RACK) testing can measure the conductance through grid fingers, as they are tensilely strained at micrometer increments to failure. The module-level mechanical stress testing and simultaneous electroluminescence imaging also allow visualizing the cracks forming in silicon substrates and electrically isolated regions.

This combination of characterization tools proves exceptionally useful for rapid product development of new, crack-tolerant, screen-printable silver pastes that would improve the lifetime of silicon PV modules against cracks and hot spots.

Core Objective

Location

Osazda Energy, LLC University of New Mexico, Georgia Institute of Technology, and National Renewable Energy Laboratory

Applications

The previously described testing capabilities for electromechanical properties and module-level reliability would be applicable for rapid screening of new silver paste formulations and advanced metallization schemes.

Availability

These capabilities are available to NREL scientists and external collaborators.

References

Abudayyeh, O.K.; Gapp, N.D.; Nelson, C.; Wilt, D.M.; Han, S.M. (2016). "Silver-Carbon-Nanotube Metal Matrix Composites for Metal Contacts on Space Photovoltaics." IEEE J. Photovolt. 6, 337-342.

Abudayyeh, O.; Gapp, N.D.; Wilt, D.M.; Han, S.M. (2016) "Methods To Mitigate Stress-Induced Metal Line Fractures for Thin-Film Solar Cells, Using Metal-Carbon-Nanotube Composites." Patent No. Application No. PCT/US2016/038197.

Abudayyeh, O.; Bradshaw, G.K.; Whipple, S.; Wilt, D.M.; Han, S.M. (2017) "Integration of Crack-Tolerant Composite Gridlines on Triple Junction Photovoltaic Cells." IEEE Photovoltaic Specialist Conference, Washington D.C.

Abudayyeh, O.; Chavez, A.; Chavez, J.; Zimbardi, F.; Rounsaville, B.; Upadhyaya, V.; Rohatgi, A.; McDanold, B.; Silverman, T.; Han, S. M. (2019) ”Development of Low-Cost, Crack-Tolerant Metallization Using Screen Printing.” IEEE PVSC-46, Chicago, IL.

Abudayyeh, O.; Nelson, C.; Chavez, A.; Chavez, J.; Shen, Y-L.; Zimbardi, F.; Rounsaville, B.; Upadhyaya, V.; Rohatgi, A.; McDanold, B.; Silverman, T.; Han, S. M. (2018) “Development of Low-Cost, Crack-Tolerant Metallization for Solar Cells." IEEE 7th World Conference on Photovoltaic Energy Conversion, Waikoloa, HI.

Han, S. M.; Abudayyeh, O. K.; Wilt, D. M.; Chavez, A. (2018) “Materials Engineering To Increase Crack-Tolerance of Screen-Printable Metal Paste.” Provisional Patent Application.

Contact

To learn more about this project, contact Sang M. Han.