Reliability of Modules with High-Efficiency Solar Cells with Copper-Plated Contacts

DuraMAT fabricates crystalline silicon (c-Si) solar cells with copper (Cu)-plated contacts on both conventional and high-efficiency cell architectures: aluminum back surface field (BSF), passivated emitter real cell (PERC), and silicon heterojunction (SHJ). We then expose the cells to environmental stress based on standard qualification protocols.

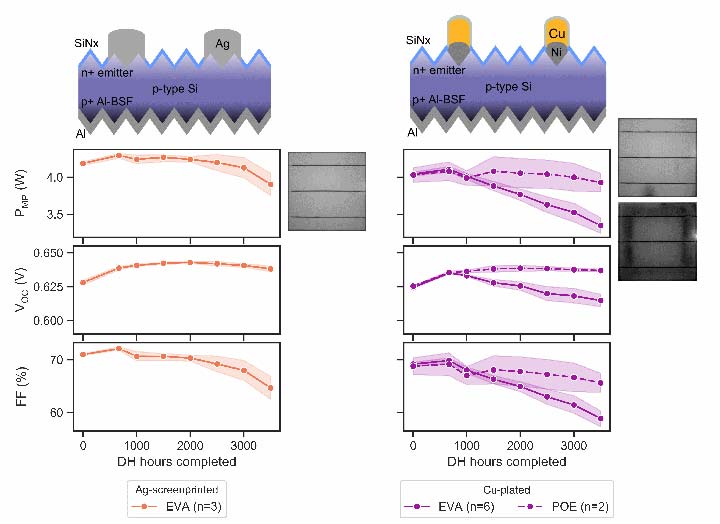

We investigate conventional and emerging encapsulants and module architectures—ethlene vinly acetate (EVA) vs. polyolefin encapsulant (POE) and glass-backsheet vs. glass-glass—to search for vulnerabilities introduced by Cu-plated contacts in a wide variety of conventional and forward-looking cell and module configurations.

For some time, Cu-plated contacts have been proposed as lower-cost, higher-performance replacements to traditional screen-printed silver contacts c-Si solar cells. Indeed, recent record efficiencies for c-Si single junction solar cells have used Cu-plated contacts. However, there are still unanswered questions about the durability and long-term reliability of Cu-based contact schemes, and limited studies in the literature specifically focused on the reliability of Cu contacts. This study aims to close that gap. Cu is a problematic impurity in c-Si, and the long-term integrity of the Cu contact needs to be maintained.

Core Objective

Location

Arizona State University’s Solar Power Laboratory (SPL) and Photovoltaic Reliability Laboratory (PRL); Tempe, AZ and Mesa, AZ

Applications

Cell manufacturers looking to adopt Cu-plated contacts will be able to use our findings to inform best practices for making long-lasting reliable contacts. Module manufacturers considering cells with Cu-plated contacts will have new data to inform balance of material and module architecture choices.

References

Joseph Karas, Archana Sinha, Viswa Sai Pavan Buddha, Fang Li, Farhad Moghadam, Govindasamy TamizhMani,

Stuart Bowden, and André Augusto, “Damp Heat Induced Degradation of Silicon Heterojunction

Solar Cells With Cu-Plated Contacts,” IEEE J. Photovoltaics, vol. 10, no. 1, pp. 153–158,

Jan. 2020, doi: 10.1109/JPHOTOV.2019.2941693.

Joseph Karas, Lynne Michaelson, Krystal Munoz, Mohammad Jobayer Hossain, Eric

Schneller, Kristopher O. Davis, Stuart Bowden, André Augusto, “Degradation of copper‐plated

silicon solar cells with damp heat stress,” Prog. Photovoltaics Res. Appl., vol. 28,

pp. 1175–1186, Aug. 2020, doi: 10.1002/pip.3331.

Contact

To learn more about this project, contact Andre Augusto or Stuart Bowden.

Degradation with increasing durations of damp heat stress for Ag-screen-printed (orange) and Cu-plated (purple) solar cell contacts. In Cu-plated contacts, we find degradation is minimized by using POE encapsulants (dotted purple line); whereas EVA (solid purple line) results in diode degradation and lifetime loss initiating at the cell edge.