Anti-Reflection Coatings for Photovoltaic Module Glass

DuraMAT is developing methods for using a white-light reflection measurement to determine the anti-reflective (AR) coating performance on fielded photovoltaic (PV) modules.

The method is non-destructive, field-portable, low-power, can be performed in full sunlight, and does not require any electrical reconfiguration of the PV array. This simple and inexpensive method can quantify AR coating degradation in the field.

In order to increase PV power production, AR coatings are included on the air-glass interface on the vast majority of PV modules. Typical AR coatings (e.g., porous silica) increase light transmission by ~3%, which is an easy and inexpensive way to increase the power produced by modules. However, the PV community does not currently know how long these AR coatings last in the field. This makes it difficult to quantify how coatings impact the levelized cost of electricity and whether more durable coatings are needed. As such, there is an urgent need to study how long typical AR coatings last in the field.

Core Objective

Location

Lawrence Berkeley National Laboratory

Applications

This method will be useful for inspecting solar modules, determining root cause of degradation and developing more robust coatings.

Availability

Publications are available for the broader PV community.

References

T. Karin and A. Jain. Visual Characterization of Anti-Reflective Coating on Solar

Module Glass. Photovoltaics Specialist Conference, 2020.

https://www.researchgate.net/publication/342452509_Visual_Characterization_of_Anti-Reflective_Coating_on_Solar_Module_Glass

Contact

To learn more about this project, contact Todd Karin.

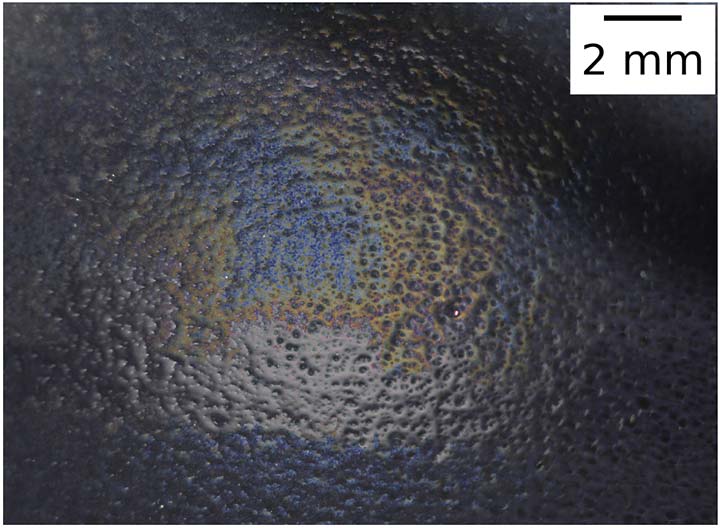

Reflected white-light image shows extreme coating loss on a PV module with 13 years aging. Image taken at the bottom edge of the module where high soiling occurs. Full coating thickness is blue, partially degraded coating is yellow and magenta, and fully removed coating is white.