Application of Acceleration Science and Validation for Combined-Accelerated Stress Test Development

DuraMAT will continue to develop combined-accelerated stress testing (C-AST) for photovoltaic (PV) products and its utility proved by reproducing field failures that do not manifest in standard test methods.

We will extend C-AST to test balance of system components and for mechanical loading to better simulate wind and snow loads for testing of full-size modules. The value proposition of C-AST is being developed through techno-economic analyses, improved data visualization, and engagement with the value chain to obtain feedback for the goal of wider adoption of the testing method. A design and method for performing C-AST outdoors using low-concentration sunlight is also planned.

C-AST applies multiple stress factors of the natural environment in combinations and in sequences in an environmental chamber with fewer samples and fewer parallel tests to accelerate the environmental stresses experienced by PV products in a more comprehensive and field representative way. Degradation rate models are being applied to estimate the acceleration factors for various degradation modes that have been found in C-AST.

For more information, see Development of Combined-Accelerated Stress Testing.

Core Objective

Disruptive Acceleration Science

Location

National Renewable Energy Laboratory (NREL), Sandia National Laboratories

Applications

This project combines the environmental stress factors including light, temperature, humidity, rain/spray, system voltage, and mechanical stress (thermo-mechanical and static loading) to reduce the number of tests, samples, and chambers required for PV module or material qualification. C-AST can therefore accelerate development, bankability, and commercialization of PV module innovations, including those with new materials and designs for which specific tests have not yet been developed.

Availability

Negotiated projects with NREL scientists and external collaborators

References

Hacke, P.; Holsapple, D.; Jankovec, M.; Kempe, M.; Luo, W.; Miller, D.C.; Mitterhofer,

S.; Owen-Bellini, M.; Spataru, S.; Sulas-Kern, D.; Tanahashi, T.; Topič, M.; Woodhouse,

M., (2020) “Establishing Module Durability with Combined-Accelerated Stress Testing.”

10th International Conference on Crystalline Silicon Photovoltaics, June 1-5, Hangzhou,

China

Woodhouse, M.; Hacke, P.; Erion-Lorico, T. (2020) “On the Costs and Benefits of Combined

Accelerated Stress Testing (C-AST) for PV Project Economics,” DuraMAT webinar, March,

2020

Contact

For more information about this project, contact Peter Hacke.

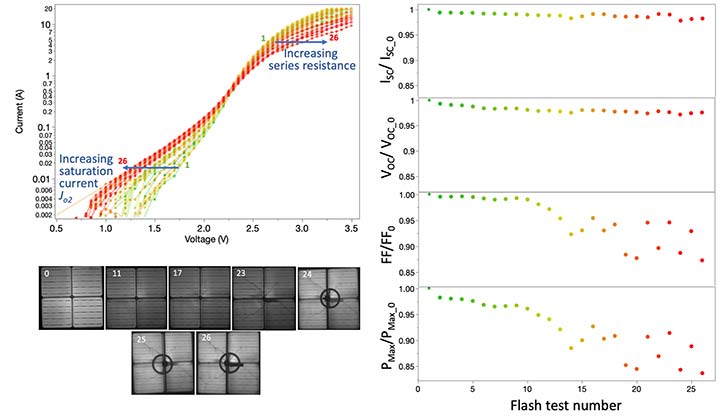

Degradation of a PERC module through C-AST including, but not limited to, effects of light-induced degradation and cell cracking. Left: Electroluminescence (EL) images (some taken in-situ as indicated by the pressure actuator in the images) and in-situ dark I-V measurements showing the increase in series resistance and saturation current (J02) associated with the degradation. Right: power degradation of this module through approximately 8 months of testing. Measurements by solar simulator and EL are shown in 26 intervals as indicated by the colored points and labels on the EL images. Green points are at the start of test and red points at the end in both plots.