New Concepts for Reliable Low-Cost Module Encapsulation and Barrier Technologies

As a DuraMAT project, Stanford University is introducing two industrially relevant new concepts to accelerate module reliability and manufacturability.

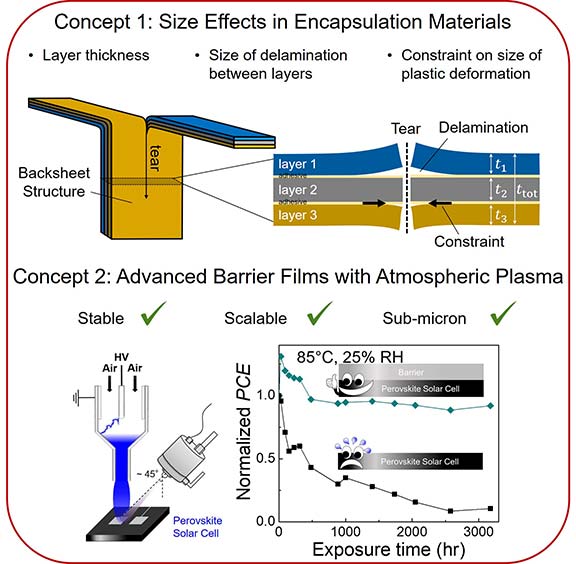

The first concept demonstrates the important role of dimensional “size effects” on material properties, especially when introducing new materials with decreasing volumes for low-cost and lightweight modules. We analyze and model the dimensional “size effects.” This includes layer thicknesses of encapsulation materials such as backsheet structures, on the overall thermomechanical properties and the effects of the interactions among the layers on fracture behaviors such as tearing and delamination. Additionally, we use X-ray scattering with collaborators at SLAC National Accelerator Laboratory to understand the effect of damp heat exposure on the polymer microstructure.

The second concept involves submicron barrier films produced rapidly in ambient by a scalable spray plasma process for low-cost, lightweight module encapsulation. The precursors range from organosilicates to oxide/nitride blends with controlled organic content, adhesion, thickness, density, and anti-reflective properties. Introducing fluorine-based precursors enables hydrophobicity and tunable morphology. The temperature of the plasma is sufficiently low to enable processing on flexible substrates. Thin-film perovskite solar cells with submicron coatings exhibit significant improvements in stability when exposed to light, heat, and moisture characterized by device performance under accelerated aging conditions and wide-angle X-ray scattering to determine degradation kinetics.

Core Objective

Location

Stanford University

Applications

Traditional encapsulants are many times thicker than the entire active device, increasing module weight and cost. To design for new, reliable module materials with decreasing volumes, the role of dimensional “size effects” on the thermomechanical and fracture properties are characterized and modelled, providing guidelines for optimal structures for reliability.

Additionally, innovative spray plasma processing is a scalable method to produce barrier films in air to provide modules with robust protection against degradation, at a fraction of the weight.

Availability

Available to DuraMAT community and external collaborators.

References

Rolston, N., Printz, A. D., Hilt, F., Hovish, M. Q., Brüning, K., Tassone, C. J.,

& Dauskardt, R. H. (2017). Improved stability and efficiency of perovskite solar cells

with submicron flexible barrier films deposited in air. Journal of Materials Chemistry

A, 5(44), 22975–22983. https://doi.org/10.1039/C7TA09178H

Yuen, P. Y., Moffitt, S. L., Novoa, F. D., Schelhas, L. T., & Dauskardt, R. H. (2019).

Tearing and reliability of photovoltaic module backsheets. Progress in Photovoltaics:

Research and Applications, 27(8), 693–705. https://doi.org/10.1002/pip.3144

Contact

To learn more about this project, contact Reinhold Dauskardt.