Highly Instrumented Modules for Environmental Characterization and Simulation Model Validation

This DuraMAT SPARK project seeks to develop a proof-of-concept method for embedding strain gauges into photovoltaic modules, to enable in-situ measurements of a module’s mechanical state.

The goal of this effort is to both collect internal strain data for computational model validation and enable instrumented modules to be deployed in field testing to collect data on real-life environmental stress states.

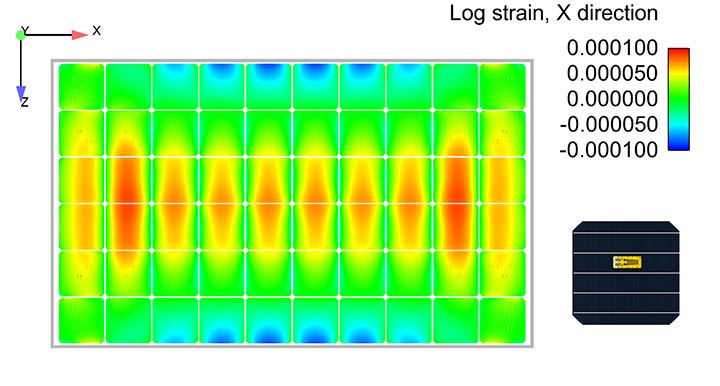

The technical approach begins by building modules with strain gauges directly laminated in place over highly strained locations identified through computational modeling. Laboratory mechanical testing will then be conducted on these modules, to correlate strain gauge output with measured loads and module shapes. These gauge outputs can be used directly for comparison and validation of simulation predicted strains,and if correlations to module shapes are found to be highly successful, instrumented modules could potentially be utilized to characterize the actual loads and deformations experienced by modules in the field.

Core Objective

Multi-Scale, Multi-Physics Modeling

Location

Sandia National Laboratories

Applications

Measurement of internal strain is a precursor for understanding the driving forces behind module degradation modes such as cell cracking and interconnect damage. Successful demonstration of this capability helps to develop and validate damage models and characterize how environmental exposures can affect components inside the module packaging.

Availability

Conclusions and lessons learned to be made available throughout DuraMAT Consortium.

References

Ashley Maes, James Hartley, Mike Rowell, Charles Robinson, Tariq Khraishi. “Instrumented Modules for Mechanical Environment Characterization and Simulation Model Validation”. 47th IEEE Photovoltaics Specialists Conference. Virtual. June 15 -August 21, 2020.

Contact

To learn more about this project, contact James Hartley.

Figure 1. Photoluminescence (PL) image of an encapsulated solar cell with attached strain gauge instrumentation. Embedding gauges directly within the laminate allows internal strain quantities to be measured.

Figure 2. Simulated module strain in X direction during a 2400 Pa front side pressure load test. Embedded strain gauges report measured strain at strategic locations, to validate simulation output.